Tubular Dowel Bars

Raising the bar in road construction

The O-Dowel bar is a carbon steel tubular dowel bar that’s improving highway construction, from new jointed pavement concrete construction to full-depth repairs. Due to its hollow construction, it is lighter, safer and more durable than conventional solid steel dowel bars.

Looking for a sustainable dowel bar? At half the weight of a conventional solid steel dowel bar, the O-Dowel tubular dowel bar is an excellent sustainable dowel bar choice. The O-Dowel also affords faster installations, fewer safety risks and better freight efficiencies.

DOT approvals

Millions of feet of O-Dowel tubular dowels have been installed. O-Dowel has been approved by the following states. Join us.

The O-Dowel Edge

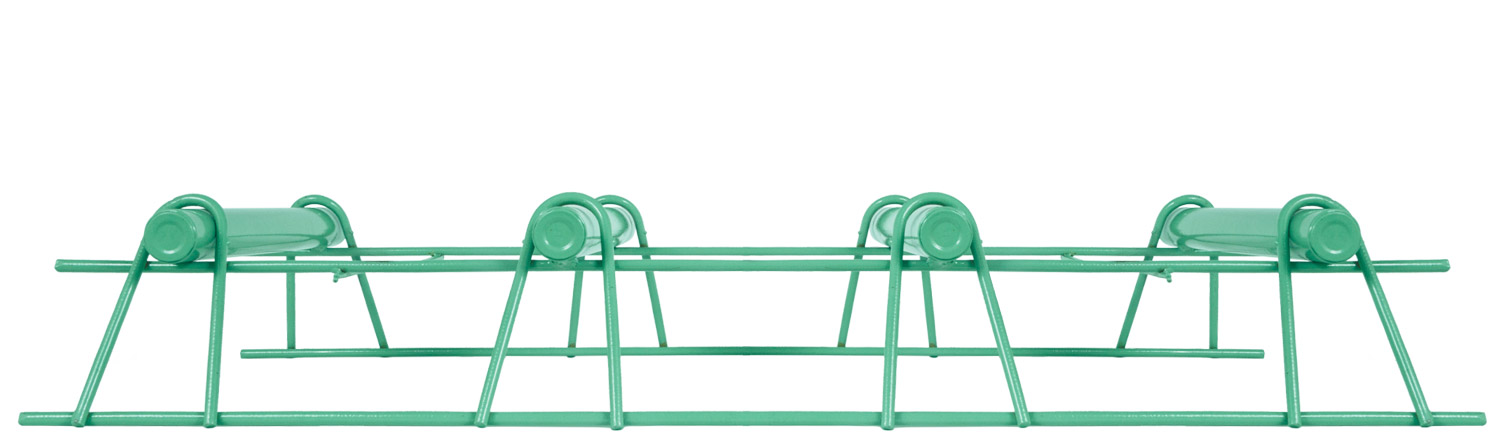

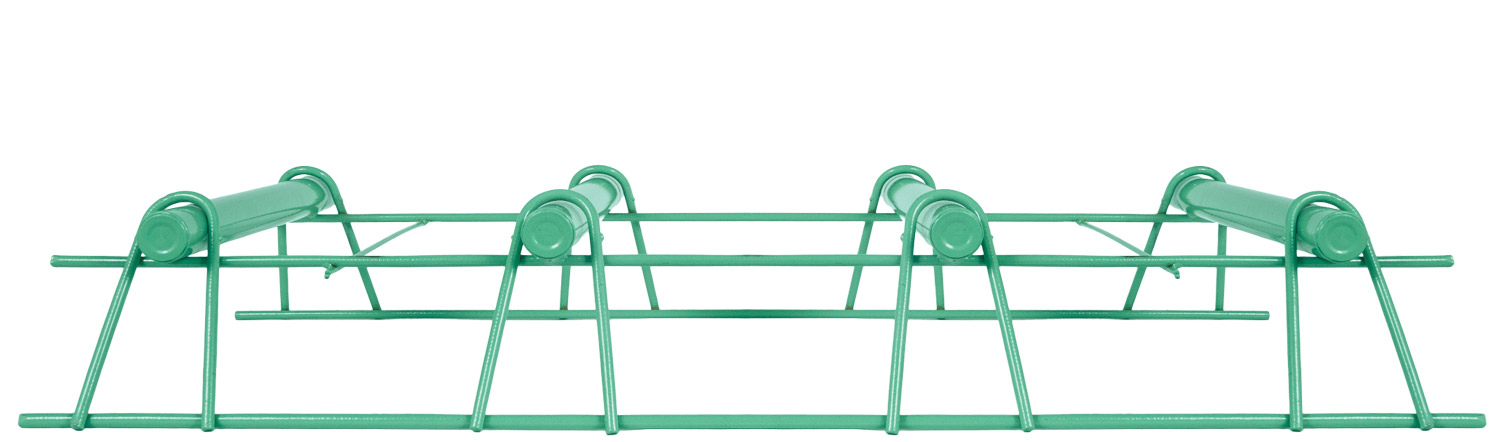

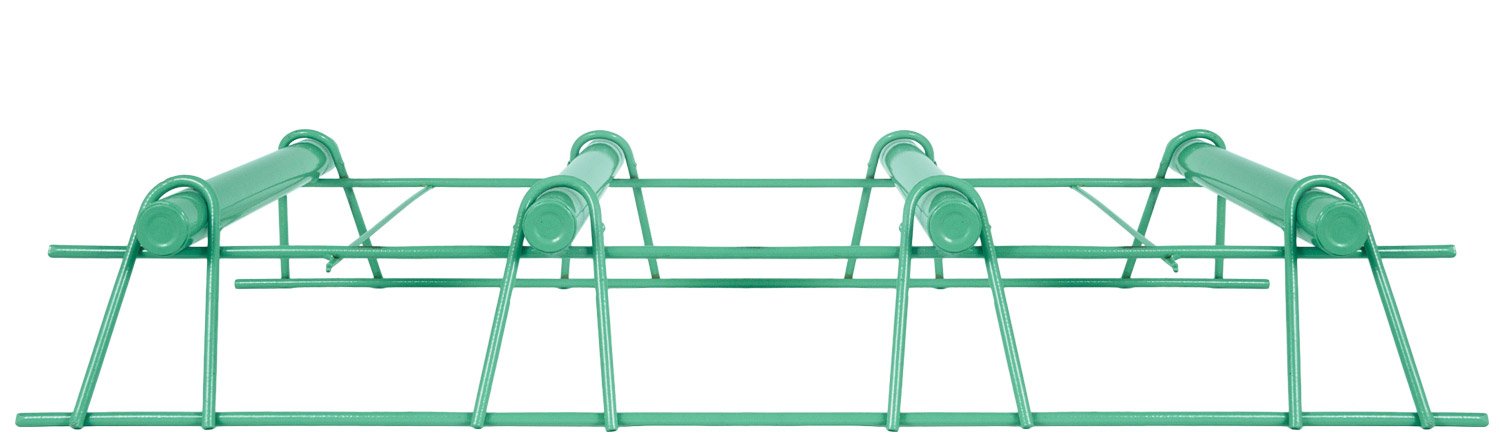

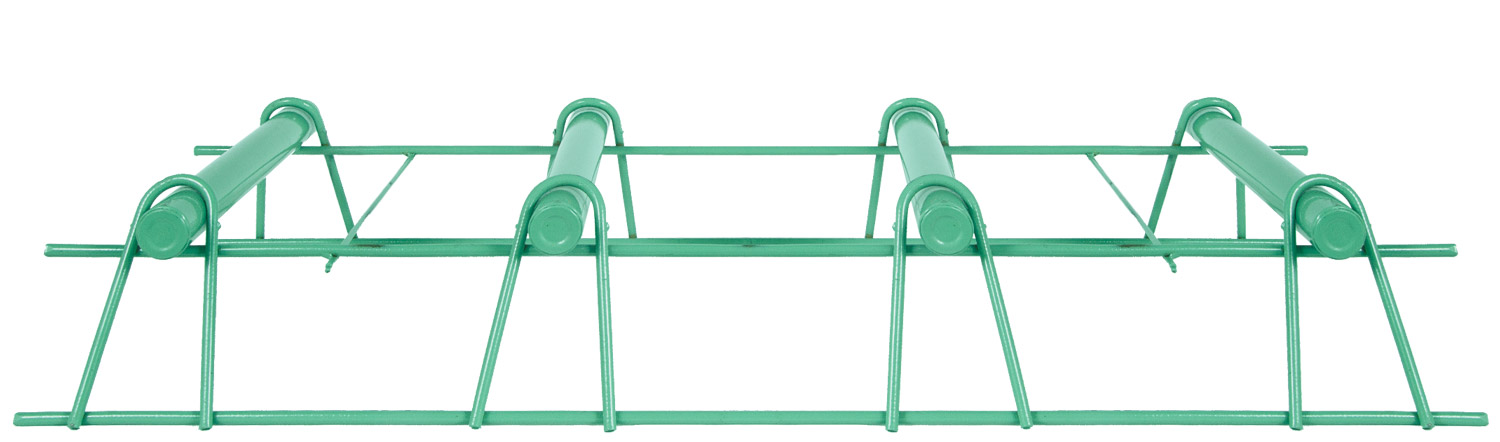

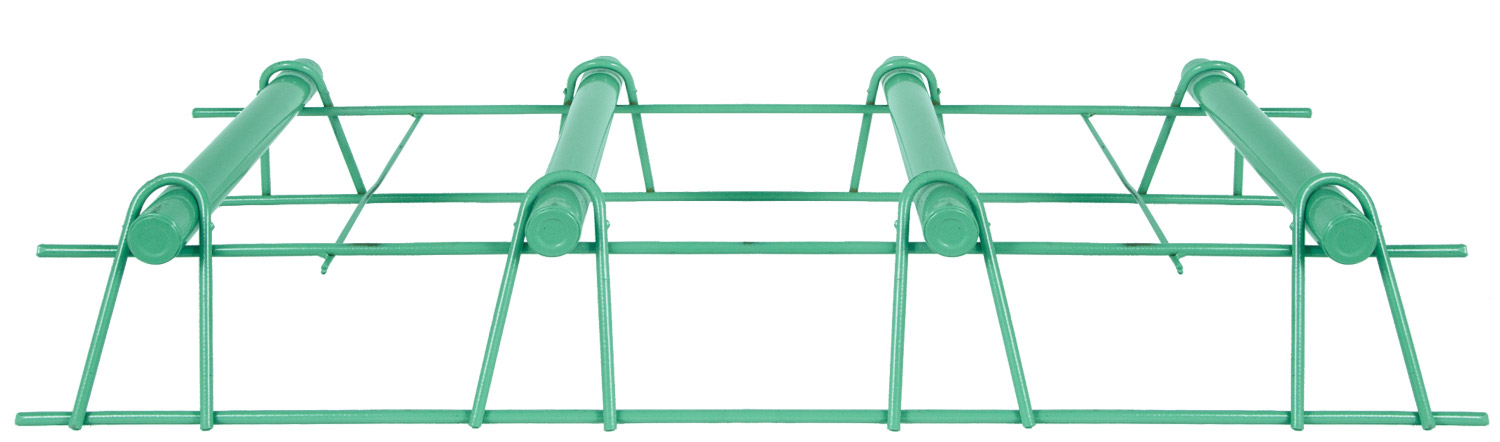

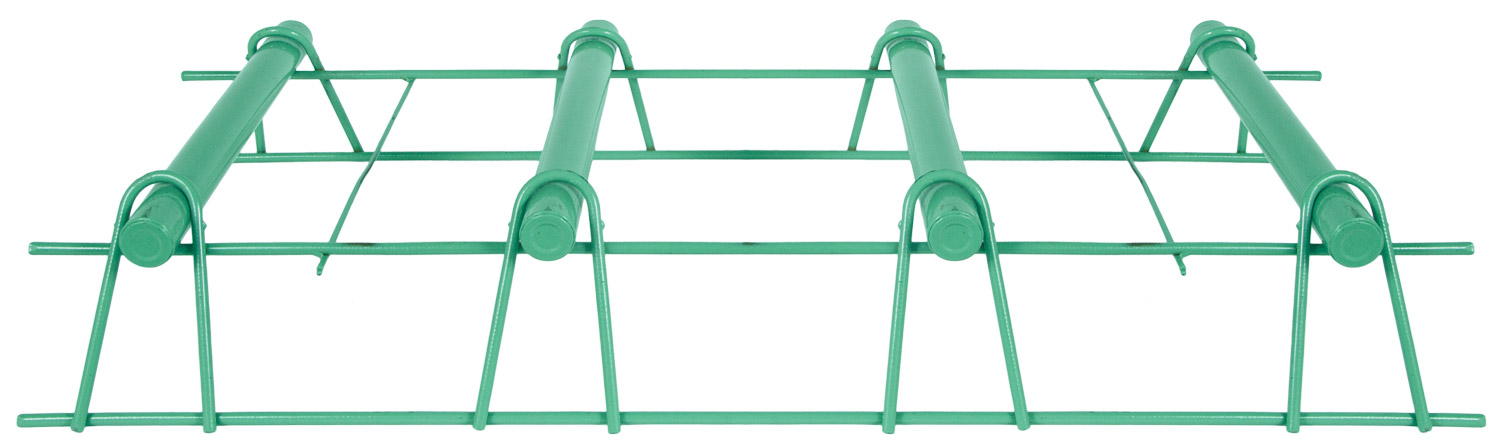

An O-Dowel basket weighs about half that of a conventional solid dowel bar basket, delivering cost savings across the construction process. The O-Dowel promotes ease of installation, reduces the threat of injuries, helps reduce insurance costs and allows for more units to be shipped per truckload. Plus, it’s a 100% recyclable solution.

The O-Dowel performs to the same structural standards as solid steel dowels yet provides superior resistance to corrosion, with galvanized coating on the inside and outside of the O-Dowel making it more corrosion-resistant than a solid, epoxy-coated dowel bar. End caps offer further safeguards.

A BETTER DOWEL BAR ALTERNATIVE

Sustainable & Green

We’re committed to a brighter and more sustainable future which is why the O-Dowel is made from 100% recycled steel and is 100% recyclable after the road’s useful life using conventional recycling methods. And because there is less than 1/2 of steel used in O-Dowel vs. a typical solid dowel, fewer truckloads are needed to ship the O-Dowel. That means a lower carbon footprint for everyone.

Durable

With state DOT-specific conventional epoxy coating on the exterior and a galvanized surface on both its interior and exterior, every O-Dowel has an extra layer of corrosion resistance. Many states use O-Dowel in long-live paving / 50 year+ design-life.

Strong

A heavy wall thickness to outside diameter ratio provides the O-Dowel with performance characteristics comparable to those of a solid steel bar.

Lightweight

High-strength structural steel tubing creates a lightweight alternative to solid-steel bars, enhancing the economics across the construction spectrum.

Manufactured in the USA

O-Dowel is committed to the continued growth and prosperity of our great nation, which is why we proudly manufacture all our products in the USA. From employing Americans across all facets of our business to assembling all of our dowel bars here at home. Even the high-quality components used in manufacturing our dowel bars and associated parts come from the USA. We are proud to say that O-Dowel is American made.

*These materials meet the requirements of Federal Highway Administration (FHWA) Buy American requirements as specified in Title 23 of the Federal Code of Regulations (CFR) Section 635.410, section 1605 of the American Recovery and Reinvestment Act (ARRA) of 2000, CFR 49, Section 50101, and of the Buy American, Build America (BABA) Act of the Infrastructure and Jobs Act (IIJA).